Products & Services

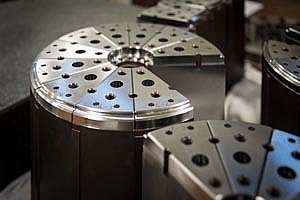

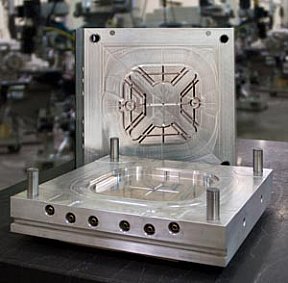

Molds

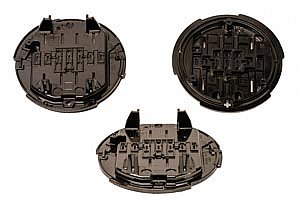

Designing, building, and repairing plastic injection molds is the core of our business. Our customer base includes a wide variety of industries with Medical being at the top of our list. Superior Tooling serves industries such as Medical, Health Care, Electrical, Industrial, Packaging, Automotive, Aerospace, and others.

The molds we manufacture range from single cavity cold runner molds to larger more complex 64 cavity and higher hot runner molds with side actions, lifters, and other complex features including stack molds, two shot molds, and overmolds.

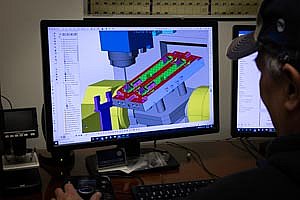

All of our plastic injection molds are designed in-house using the latest software and computer technology.

Engineering

Behind every quality mold is a carefully thought-out design. Superior Tooling's engineering is second to none, using innovative concepts to solve difficult problems in the design and manufacturing process. Our team of mold manufacturing professionals combine years of experience in design for manufacturing, high volume production, fast cycle times, and mold longevity.

Engineering Services

Mold and Die Design

Design for Manufacture (DFM)

Mold Flow Analysis

Fixture Design

Reverse Engineering

Part Inspection

Tool Inspection

Tool Verification

Solid Modeling

Detailing

Reverse Engineering

In this process a CMM (Coordinate Measuring Machine) along with other software packages are used to scan the sample part. Once complete a 3-D Solid Model can be produced or the information obtained can be used for many other options. Models can be created or repairs can be made in areas that have been damaged where other information is not available Mold Design is a large part of our Engineering Department. We can design your injection molds from simple parts to complex tools, using hot runner systems, mechanical and hydraulic slides, lifters, and many other features that may be required to produce your product.

Superior Tooling uses a variety of computers and software packages to give our customers what they need. The listed items are only a small portion of our capabilities

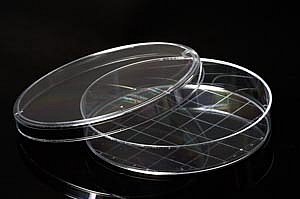

Prototypes

From concept to high-volume production, we can help you get your product to market fast. We offer machined prototype parts, as well as both aluminum and hard steel prototype molds for quick turnaround, evaluation of new product look and feel, proof of concept, and process validation.

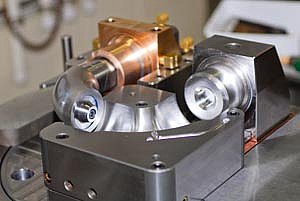

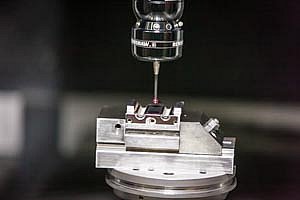

Precision Machine Work

The same equipment and personnel that build our top-notch injection molds are also available to do precision machining for almost any other application. We deliver a high standard of detailed workmanship on a variety of products and processes.

Mold Validation

Our tech center provides a private environment for setup and validation of new molds. Equipped with two presses, in-house validation ensures your molds get up and running quickly. Read more...